The Mechanical Battery Explained - A Flywheel Comeback?

Undecided with Matt Ferrell・11 minutes read

Flywheels, an older mechanical battery, are being reconsidered for energy storage due to benefits like high power density, long lifetime, and carbon-free operation, which make them attractive for renewable energy support. Despite facing high installation costs compared to lithium-ion batteries, flywheel energy storage systems offer fast response times, long lifetimes, high efficiency, and high power density, making them suitable for various applications including industrial, commercial, and grid integration.

Insights

- Flywheels, despite their historical roots, are being reconsidered for modern energy storage due to their high power density, efficiency, and carbon-free operation, making them an attractive option for supporting renewable energy sources like solar and wind.

- While Flywheel Energy Storage Systems (FESS) offer benefits such as fast response times, long lifetimes, and high efficiency, they face challenges in terms of high installation costs compared to lithium-ion batteries, making cost-effectiveness a crucial factor in determining their widespread adoption for utility-scale applications.

Get key ideas from YouTube videos. It’s free

Recent questions

What are the benefits of flywheel energy storage?

Flywheels offer high power density, long lifetime, high efficiency, and carbon-free operation, making them attractive for energy storage. They can support renewable energy like solar and wind effectively.

How do flywheels operate in energy storage?

Flywheels function as dual-function electric motors to store and generate energy, similar to regenerative braking in electric vehicles. Their rotational energy is determined by moment of inertia and angular velocity, impacting storage capacity and efficiency.

What is the history of flywheels?

Flywheels have a long history, initially used in ancient Mesopotamia for pottery wheels and later in engines during the industrial revolution. They have been utilized in various applications, including transportation, spacecraft, motor sports, and grid stabilization for renewable energy integration.

What are the key components of flywheel energy storage systems?

Flywheel energy storage systems (FESS) consist of key components like bearings, enclosures, and power electronic converters, with high-speed flywheels reaching up to 100,000 RPM. FESS have fast response times, long lifetimes of about 20 years, high efficiency of around 95%, and high power density.

What challenges do flywheels face in energy storage?

Despite their advantages, flywheels face challenges such as high installation costs, with FESS costs ranging from $1500 to $6000 per kilowatt-hour, compared to lithium-ion batteries at $200 to $1260 per kilowatt-hour for utility-scale applications.

Related videos

CNBC

The Future Of Energy Storage Beyond Lithium Ion

Innovative Techs

How gravity batteries could change the world

Thoughty2

This Is Why Companies Are Hiding The Truth About Batteries

Undecided with Matt Ferrell

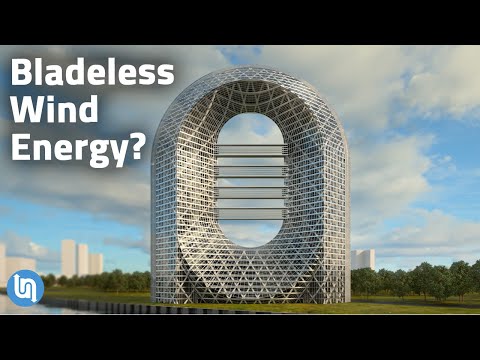

The Future of Solid State Wind Energy - No More Blades

Undecided with Matt Ferrell

How Can A Wind Turbine Be Motionless?

Summary

00:00

"Flywheels: Efficient Energy Storage for Renewables"

- Lithium-ion batteries are commonly used for energy storage, but flywheels, an old-school mechanical battery, are being reconsidered for their benefits in supporting renewable energy like solar and wind.

- Flywheels offer high power density, long lifetime, high efficiency, and carbon-free operation, making them attractive for energy storage.

- Global energy consumption in 2018 reached nearly 25,000 terawatt-hours, with solar and wind contributing only about 5% to total power generation worldwide.

- Flywheels operate as dual-function electric motors to store and generate energy, similar to regenerative braking in electric vehicles.

- The rotational energy of a flywheel is directly related to its moment of inertia and angular velocity, impacting its storage capacity and efficiency.

- Flywheels have a long history, initially used in ancient Mesopotamia for pottery wheels and later in engines during the industrial revolution.

- Flywheels have been utilized in various applications, including transportation, spacecraft, motor sports, and grid stabilization for renewable energy integration.

- Flywheel energy storage systems (FESS) consist of key components like bearings, enclosures, and power electronic converters, with high-speed flywheels reaching up to 100,000 RPM.

- FESS have fast response times, long lifetimes of about 20 years, high efficiency of around 95%, and high power density, making them suitable for industrial, commercial, and grid applications.

- Despite their advantages, flywheels face challenges such as high installation costs, with FESS costs ranging from $1500 to $6000 per kilowatt-hour, compared to lithium-ion batteries at $200 to $1260 per kilowatt-hour for utility-scale applications.