The Making of a Wind Turbine | Exceptional Engineering | Free Documentary

Free Documentary・31 minutes read

High-tech turbines are crucial for green energy worldwide, requiring efficient manufacturing methods for massive rotor blades and precise assembly to avoid errors. The booming wind turbine industry involves laying foundations, hoisting tower segments, and transporting components with special ships and equipment, culminating in the generation of green energy once the turbine is operational.

Insights

- Wind turbine manufacturing involves precise assembly processes, including the meticulous construction of rotor blades using fiberglass, foam cores, and resin injections to ensure stability and efficiency. These blades undergo extensive fatigue testing, lasting up to 12 weeks, to simulate forces over their lifespan, with new designs tested for loads equivalent to 25 years of use, showcasing the rigorous quality control measures in place.

- The assembly of wind turbines, particularly offshore, requires specialized equipment and procedures, such as the use of massive cranes and installation ships. The process involves lifting enormous rotor stars, some of the largest globally at 81 meters in length, with a surface area of 20,000 square meters, and weighing around 56 tonnes, to a vertical position near the tower. This intricate operation, conducted at heights of 138 meters above ground, showcases the complexity and engineering precision necessary for wind energy generation.

Get key ideas from YouTube videos. It’s free

Recent questions

How are wind turbine rotor blades constructed?

Rotor blades for wind turbines are meticulously constructed with fiberglass matting, foam cores, and resin injections for stability and efficiency. These blades undergo rigorous fatigue tests lasting up to 12 weeks to simulate the forces they will face over their lifespan. Prototypes and new designs are tested for loads equivalent to 25 years of use. Testing programs for a blade can last up to a year, with sensors measuring various parameters 25 times per second during testing.

What is the process of assembling a wind turbine?

Wind turbine assembly involves laying a massive foundation, hoisting tower segments with precision, and attaching rotor blades meticulously constructed with fiberglass matting, foam cores, and resin injections. Special ships, platforms, and cranes are essential for transporting turbine components. Crew members safely descend using steel cables made of nine strands, each reel holding 485 meters of cable. The crew boards a platform basket to reach the top of the tower, avoiding strenuous ladder climbing. Once the rotor star is raised to a vertical position and attached to the generator in the nacelle 138 meters above ground, the wind turbine becomes operational.

What are the challenges in manufacturing wind turbines?

Manufacturing wind turbines involves the construction of massive rotor blades, transportation of components using special ships and cranes, and precise assembly to avoid deadly errors. The process requires efficient manufacturing methods for larger turbines, with a focus on quality control and technological advancements. Offshore wind turbines, in particular, require special ships, platforms, and foundations for installation. The manufacturing industry is booming globally, driven by the demand for green energy and the competitive nature of wind energy due to cost reductions.

How are wind turbine components transported?

Wind turbine components are transported using special ships, transporters, and cranes due to their massive size and weight. Rotor blades, tower segments, and other parts are carefully moved to the assembly site to ensure precision during the construction process. Offshore wind turbines require additional logistical planning, with platforms and foundations needing to be transported and installed using specialized equipment. The transportation of these components is crucial for the successful assembly and operation of wind turbines.

What is the capacity of high-tech wind turbine cells?

The high-tech cells produced in a factory in Denmark for wind turbines have a capacity rating of 3.2 megawatts. These cells are used in the assembly of direct-drive wind turbines, with generators operating like oversized bottle dynamos. The assembly line in the factory moves forward every 4 hours and 20 minutes, focusing on efficiency and quality control to meet the growing demand for green energy worldwide.

Related videos

The Engineering Mindset

How Wind Turbines Really Work: The Hidden Secrets

Undecided with Matt Ferrell

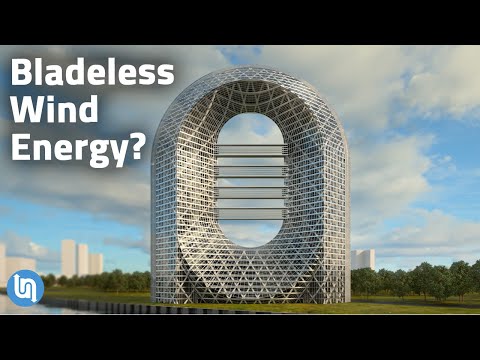

The Future of Solid State Wind Energy - No More Blades

Undecided with Matt Ferrell

How Can A Wind Turbine Be Motionless?

Just Have a Think

Aeromine Rooftop Wind. Static. Silent. 50% more power than Solar PV. What's not to like?

Technical Engineering School

How to Steam Turbine components work? Power Engineering

Summary

00:00

"Wind turbine technology revolutionizes green energy"

- High-tech turbines are crucial for green energy worldwide.

- Larger turbines require more efficient manufacturing methods.

- Rotor blades are massive, over 80 meters long and 20 tons in weight.

- Special ships, transporters, and cranes are essential for transporting turbine components.

- Wind turbine assembly requires precision to avoid deadly errors.

- Wind turbine manufacturing is a booming industry globally.

- Building a wind turbine involves laying a massive foundation.

- Tower segments are carefully hoisted and positioned with precision.

- Offshore wind turbines require special ships, platforms, and foundations.

- Wind energy is competitive due to technological advancements and cost reductions.

21:55

"Wind turbine assembly: precision and efficiency"

- The tower has almost 300 rungs and widens towards the bottom, requiring strength and stamina for descent.

- Crew members safely descend using steel cables made of nine strands, each reel holding 485 meters of cable.

- Cables are attached at the foundation and pulled up through shafts using a motorized unreeling device.

- Crew boards a platform basket to reach the top of the tower, avoiding strenuous ladder climbing.

- 24 steel cables extend from the top to the basement, ensuring structural stability.

- The factory in Denmark produces high-tech cells for wind turbines, with a capacity rating of 3.2 megawatts.

- Assembly line moves forward every 4 hours and 20 minutes, with a focus on efficiency and quality control.

- Direct-drive wind turbines are assembled in the factory, with generators operating like oversized bottle dynamos.

- Crew installs 648 magnets in the generator, ensuring high magnetic strength and safety during assembly.

- Rotor blades for wind turbines are meticulously constructed, with fiberglass matting, foam cores, and resin injections for stability and efficiency.

43:51

Manufacturing and Installing Enormous Wind Turbine Blades

- Blades for wind turbines need to be carefully manufactured and transported, requiring big cranes and installation ships. They undergo rigorous fatigue tests lasting up to 12 weeks, simulating forces they'll face over their lifespan, with prototypes and new designs tested for loads equivalent to 25 years of use. Testing programs for a blade can last up to a year, with sensors measuring various parameters 25 times per second during testing.

- The enormous blades from Aalborg, 81 meters in length with a surface area of 20,000 square meters, are amongst the largest globally. They are used in offshore wind turbines with a capacity of seven to eight megawatts. During assembly, the rotor star is lifted by a crane and turned upright in the air near the tower, with a maximum wind speed of 6 meters per second allowed for safety.

- Once the rotor star, weighing about 56 tonnes and the size of half a soccer field, is raised to a vertical position, it is attached to the generator in the nacelle 138 meters above ground. After four weeks of work, the wind turbine is operational and will start generating green energy automatically when the wind speed reaches two meters per second.