Origins of Precision

Machine Thinking・25 minutes read

Precision tools and measurements are vital for modern manufacturing, from surface plates to gauge blocks, ensuring accuracy and uniformity in production. Historical units of measurement evolved into the standardized metric system, with innovations like the parametric fam and Johansson blocks revolutionizing precision measurement.

Insights

- Precision in manufacturing hinges on foundational elements like surface plates, gauge blocks, and standardized units of measure, ensuring accuracy and consistency in production processes.

- Karl Edouard Johansson's invention of gauge blocks, popularized by Ford during World War II, revolutionized precision measurement in manufacturing, setting the standard for accuracy and influencing entire industries with its universal applicability.

Get key ideas from YouTube videos. It’s free

Recent questions

What is the significance of the surface plate in manufacturing?

The surface plate is crucial in achieving dimensional precision in modern manufacturing. It serves as the foundation for creating tools like straight edges, essential for transferring precision into machines like lathes and milling machines. While not visible in final products like phones, the surface plate plays a vital role in ensuring the accuracy and precision of modern machinery.

How did the creation of the metric system impact measurements?

The creation of the metric system, based on natural measurements like the meter, aimed to provide a universal and reproducible standard. The meter's accuracy was crucial, as many other measurements, like volume and weight, were derived from it. This standardization allowed for consistency and accuracy in measurements across various industries and applications.

What role did gauge blocks play in precision measurement?

Gauge blocks, like Jo blocks, revolutionized precision measurement in manufacturing. Invented by Karl Edouard Johansson, these blocks allowed for adjustable and accurate gauges, ensuring consistent accuracy in manufacturing processes. Gauge blocks are essential for precision measurements, especially when checking micrometers, and have become a cornerstone in ensuring accuracy in various industries.

How did different inch standards impact manufacturing during World War II?

In World War II, the issue of different inch standards arose, with at least three standards existing for the inch measurement. This discrepancy led to confusion and inefficiencies in manufacturing processes. To address this, Canada established that one inch equaled exactly 25.4 millimeters, followed by the US and UK, setting a universal standard for the inch measurement and promoting consistency in manufacturing.

What is the role of NIST in ensuring precision measurements?

The National Institute of Standards and Technology (NIST) in the US certifies measuring devices to meet strict standards, ensuring precision in measurements across various industries. By setting and maintaining these standards, NIST plays a crucial role in upholding accuracy and consistency in manufacturing processes.

Related videos

Machine Thinking

The HIDDEN Screws of PRECISION

Magnet Brains

Motion and Measurement of Distances Full Chapter Class 6 Science | NCERT Science Class 6 Chapter 10

Stephen Starnes

Chemistry 1311 Chapter 1-2 Measurements on matter - SI system

DP Education - A/L සිංහල මාධ්යය

Measurement | Practical No 02 - Usage of the micrometer screwgaugae | A/L Physics Practical

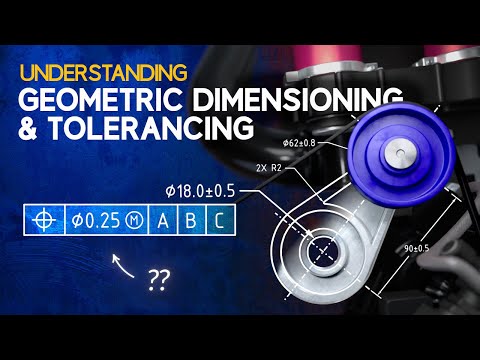

The Efficient Engineer

Understanding GD&T

Summary

00:00

Evolution of Precision Tools in Manufacturing

- The journey of precision tools and measurements began with the realization of the importance of straight lines and regular intervals in manufacturing.

- A time machine, made of complex parts like the parametric fam and turbo, symbolizes the need for precision tools.

- Creating a perfectly flat surface, like a surface plate, is crucial for achieving dimensional precision in modern manufacturing.

- The surface plate serves as the foundation for creating tools like straight edges, essential for transferring precision into machines like lathes and milling machines.

- The surface plate, though not visible in final products like phones, is integral in ensuring the precision of modern machinery.

- Historical units of measurement, derived from nature or the human body, were eventually standardized for accuracy and uniformity.

- The creation of the metric system, based on natural measurements like the meter, aimed to provide a universal and reproducible standard.

- The meter's accuracy was crucial, as many other measurements, like volume and weight, were derived from it.

- Karl Edouard Johansson's invention of gauge blocks revolutionized precision measurement in manufacturing, allowing for adjustable and accurate gauges.

- Ford's collaboration with Johansson popularized gauge blocks, ensuring consistent accuracy in manufacturing during World War II and beyond.

17:50

"Precision Measurement Standards in Manufacturing"

- In World War II, the issue of different inch standards arose, with at least three standards existing for the inch measurement.

- In 1951, Canada established that one inch equaled exactly 25.4 millimeters, followed by the US and UK.

- Johansen had set the standard for one inch at 25.4 millimeters back in 1923, influencing entire industries.

- Gauge blocks, like Jo blocks, are crucial for precision measurements, especially when checking micrometers.

- NIST in the US certifies measuring devices to meet strict standards, ensuring precision in measurements.

- Precision in manufacturing relies on foundational elements like the surface plate, agreed-upon units of measure, and gauge blocks.

- The book "Foundations of Mechanical Accuracy" by Wayne Moore delves into ultra-precise measurement techniques and history.

- Johansson blocks allow for over 260,000 measurements, with intricate calculations determining the blocks needed for specific measurements.