Inside (ONE) Our Next Energy's New Michigan Factory!

Munro Live・27 minutes read

The pre-production line in Warren, Michigan creates lithium iron phosphate cells for automotive applications, sourcing North American materials and operating on a small scale for qualification. The production process involves vacuum drying, cooling, expanding to 800 volts, and thorough testing to ensure quality and safety.

Insights

- The pre-production line for Michigan-made cells in Warren, Michigan has a capacity of 20 Gatt hours over three years, focusing on sourcing North American materials for lithium iron phosphate cells and utilizing a pilot factory to test new materials and suppliers before full-scale production.

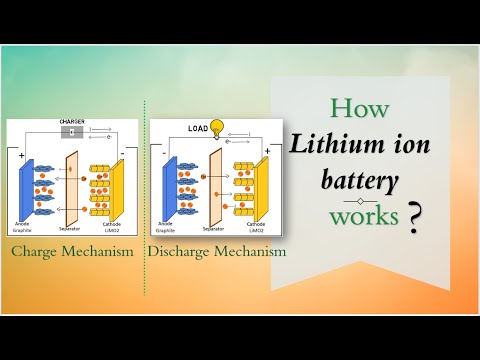

- The production process involves intricate steps such as coating cathode and anode materials on foils, managing cell expansion with compliance layers, and implementing cooling mechanisms for fast charging, highlighting the complexity and attention to detail required in manufacturing automotive lithium-ion cells.

Get key ideas from YouTube videos. It’s free

Recent questions

How are lithium iron phosphate cells produced?

The process begins with mixing cathode materials, coating them on aluminum foil to create electrodes, then coating anode material on copper foil, drying, calendaring, and stacking electrodes with separators to build lithium-ion cells.

What is the purpose of the pilot factory?

The pilot factory operates on a smaller scale to qualify new materials and suppliers before full production of prismatic metal cans for automotive applications.

How is expansion managed during cycling?

Compliance layers are used to handle cell swelling, designed to manage up to 0.5 mm of expansion per cell during cycling.

What is crucial for fast charging in battery packs?

Cooling is crucial, with cells mounted onto cold plates to dissipate heat, especially during fast charging from 10% to 80% in 12 minutes.

How is the voltage increased to 800 volts?

Transitioning to 800 volts involves doubling the number of cells in the battery pack to 240 cells, adjusting cell thickness for higher voltage, and using equipment capable of producing various cell sizes.

Related videos

CNBC

Why The EV Industry Has A Massive Supply Problem

TESLA CAR WORLD

There are 3 NEW Futuristic Battery Tech for 2024! Elon Musk's proof it works!

DW Español

Sodio, el invento chino que podría destronar a las baterías de litio

Owl WiS

How lithium ion battery works | Working principle

Insider News

Where 6 Metals Used For Electric Cars Come From | True Cost | Insider News

Summary

00:00

Michigan Factory Produces Lithium-Ion Cells for Automotive

- The pre-production line for Michigan-made cells for Automotive applications is located in Warren, Michigan, with a total capacity of 20 Gatt hours over a 3-year period.

- The factory sources North American materials for the production of lithium iron phosphate (LFP) cells.

- The process begins with the mixing of cathode materials, including powders, binders, and solvents, which are then coated on aluminum foil to create electrodes.

- The anode material, graphite, is coated on copper foil using a slot die and then dried and calendared for compression.

- The pilot factory operates on a smaller scale to qualify new materials and suppliers before full production.

- The cells produced are prismatic metal cans for automotive applications, aiming to provide the same range as nickel cobalt batteries without the associated risks.

- The production process includes vacuum drying ovens to remove water from the electrodes before stacking them with separators to build lithium-ion cells.

- The dry cells are then placed in metal cans, welded together, filled with electrolyte, and undergo a charge and discharge cycle.

- The process involves inserting the jelly roll into the metal can using a cradle for structure and managing expansion during cycling.

- Compliance layers are used to handle the swelling of cells during cycling, with a design to manage up to 0.5 mm of expansion per cell.

15:44

Optimizing Battery Pack Cooling and Voltage Transition

- Cooling is crucial in battery packs, with cells mounted onto cold plates to dissipate heat.

- Fast charging from 10% to 80% in 12 minutes requires cooling on both top and bottom with two cold plates.

- Transitioning from 400 to 800 volts involves doubling the number of cells in the battery pack to 240 cells.

- Cell thickness is adjusted for higher voltage, with equipment capable of producing various cell sizes.

- Increasing voltage to 800 volts may not halve charging time due to power constraints and cell limitations.

- After inserting the jelly roll, welding is done to seal the can and cap completely.

- Helium gas is used for leak testing, followed by electrical tests to check potential, internal resistance, and slot integrity.

- Electrolyte is added in stages to ensure complete absorption and gas removal, with a settling period at high temperature.

- Initial charging after electrolyte addition involves degassing and welding to complete the process.

- Yield rates in production are expected to start at 40% and gradually increase to 90% over six months, with scrapped materials recycled.