How Wind Turbines Really Work: The Hidden Secrets

The Engineering Mindset・19 minutes read

Wind turbines vary in size and are used to convert wind energy into electrical energy, with larger turbines being more efficient but requiring higher placement for optimal performance. The design of wind turbines includes components such as blades made of reinforced glass fiber, a gearbox to control rotational speed, and a doubly fed induction generator that maintains a constant 60 HZ output by adjusting rotor current frequency based on speed.

Insights

- Wind turbines vary in size and purpose, from small-scale applications like powering LEDs to large-scale turbines that can supply electricity to entire towns by converting wind's kinetic energy into mechanical and then electrical energy.

- The design and placement of wind turbines are crucial factors for efficiency, with considerations such as blade size, height, number of blades, and rotor speed impacting energy production. Additionally, the technology behind wind turbines involves complex components like generators, gearboxes, and control systems to ensure optimal performance and output consistency.

Get key ideas from YouTube videos. It’s free

Recent questions

How do wind turbines generate electricity?

Wind turbines convert wind's kinetic energy into mechanical energy, then electrical energy through a generator attached to a DC motor. Larger blades capture more wind energy efficiently.

What are the benefits of placing wind turbines at sea?

Wind turbines are often placed at sea due to space constraints, although land installation is cheaper and easier. Sea placement allows for larger turbines and more efficient energy generation.

What materials are wind turbine blades typically made from?

Wind turbine blades are usually made from reinforced glass fiber for strength and lightness, allowing them to efficiently capture wind energy.

Why are three blades considered the most efficient choice for wind turbines?

Wind turbines with three blades are the most efficient and cost-effective choice, providing stability, optimal energy production, and ease of stopping, making them a popular design choice.

How is the rotational speed of wind turbines controlled?

The rotational speed of wind turbines is controlled using a magnet and coil system, with a gearbox increasing the speed by around 100 times. This results in the need for only 18 RPM of the hub for the blades to achieve the desired outcome.

Related videos

OffGrid406

Watch this before you buy a wind generator, My personal experience, and what to look for

Free Documentary

The Making of a Wind Turbine | Exceptional Engineering | Free Documentary

Kris Harbour Natural Building

Off Grid 2 KW Axial Flux Wind Turbine And MPPT Dump Load Controler Build

Undecided with Matt Ferrell

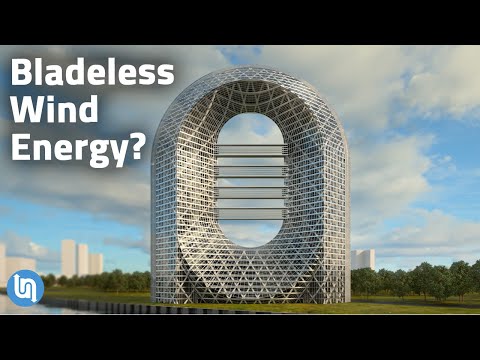

The Future of Solid State Wind Energy - No More Blades

Technical Engineering School

How to Steam Turbine components work? Power Engineering

Summary

00:00

Wind turbines: sizes, energy conversion, and placement.

- Wind turbines come in various sizes, from basic ones powering small LEDs to mega turbines powering entire towns.

- The kinetic energy of wind is converted into mechanical energy, then electrical energy by wind turbines.

- Wind turbines can be used to generate electricity by attaching a generator to a simple DC motor.

- Larger blades capture more wind energy, but they need to be higher off the ground for efficiency.

- Large turbines are often placed at sea due to space constraints, although land installation is cheaper and easier.

- Wind turbines require a strong foundation, sometimes floating on platforms in deep waters.

- Wind turbines need to face the wind, with upwind turbines being more efficient but requiring stronger blades.

- Inside a large wind turbine tower, components include access ladders, power cables, transformers, and generators.

- Blades of wind turbines are typically made from reinforced glass fiber for strength and lightness.

- The number of blades on a wind turbine affects its stability, energy production, and ease of stopping, with three blades being the most efficient and cost-effective choice.

16:25

"Wind turbine speed control and generator basics"

- By utilizing a magnet and coil, the rotational speed of a wind turbine can be controlled, with the gearbox increasing the speed by around 100 times, resulting in a need for only 18 RPM of the hub for the blades to achieve the desired outcome.

- The doubly fed induction generator comprises a rotor with three sets of coils connected to slip rings, and a stator with three sets of coils inside. The rotor's rotation induces a voltage into the stator coils, generating an AC current exported to the grid, with the controller adjusting the frequency to maintain a 60 HZ output.

- To achieve the desired 60 HZ output, adjustments are made to the rotor current frequency based on the rotor speed, with the controller ensuring a constant 60 HZ output. Brilliant offers courses covering essential engineering principles, including electricity, magnetism, and programming, with a 30-day free trial and an app for convenient learning.