How It Was Made: THE COMMODORE 64 factory tour

Retro Recipes・12 minutes read

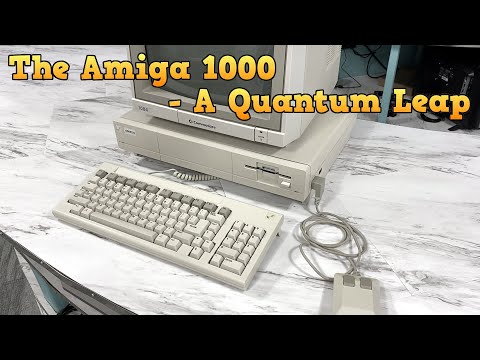

The Commodore 64, launched in 1982, was the best-selling home computer ever with over 17 million units sold, and its manufacturing process involved cutting-edge technology and precision to create millions of transistors on a single silicone plate. Companies like Commodore used chip technology independently to enable high integration and precision at low prices.

Insights

- The Commodore 64, launched in 1982, holds the title of the best-selling home computer, with over 17 million units sold, marking a significant milestone in the history of personal computing.

- The intricate manufacturing process of the Commodore 64 involved cutting-edge technologies like photo masking, chemical treatments, and electronic function testing, showcasing the meticulous attention to detail and security measures implemented to protect trade secrets and ensure high-quality production standards.

Get key ideas from YouTube videos. It’s free

Recent questions

How many units of the Commodore 64 were sold?

17 million units

What inspired the limited series using archive footage?

Canadian CTV show "How It's Made"

Who played a significant role in the creation of the Commodore 64?

Jack Trammell

What technology replaced electron tubes in the Commodore 64?

Transistors

How were the chips for the Commodore 64 manufactured?

Silicon wafers from sand

Related videos

Summary

00:00

"Commodore 64: From Concept to Creation"

- The Commodore 64 computer was launched 40 years ago in January 1982, becoming the best-selling home computer ever with over 17 million units sold.

- Archive factory footage from commodore.ca was used in a limited series inspired by the Canadian CTV show "How It's Made," translated from German and restored using machine learning.

- The vision of a future with home computers began in the 1950s and 60s, with Jack Trammell producing electronic calculators and typewriters, leading to the creation of the Commodore 64 in 1982.

- Transistors, tiny electronic switches, replaced electron tubes like those in the Colossus, offering more efficiency and affordability, allowing for millions of transistors on a single silicone plate.

- Companies like Commodore used their chip technology to design tailor-made chips independently of the global market, enabling high integration and precision at low prices.

- The manufacturing process of the Commodore 64 began with silicon wafers made from sand, with each wafer containing thousands of circuits drawn into computer-aided design software.

- The production involved creating production masks, recording digitized chip construction plans on magnetic tape, and closely guarded security to protect trade secrets.

- The wafers underwent processes like photo masking, chemical treatments, diffusion furnace heating, ion implantation, and electronic function testing to create the microprocessor.

- The chips were then tested, separated into individual chips, housed in ceramic or plastic, connected with gold threads, inspected, and sorted based on characteristics before being packed.

- The chips were assembled onto the Commodore 64's motherboard in production facilities in Asia and Germany, undergoing rigorous physical and software testing before final assembly, testing, and packaging.