A Day in the Life of Sustainable Beer: New Belgium Brewery

The Rational Middle・4 minutes read

New Belgium brewery in Colorado prioritizes environmental stewardship and innovation in their brewing process to save energy, water, and be a better employer. They utilize natural light in their brew house, transfer liquid waste to farmers for cattle feed, and treat process wastewater on-site to showcase their commitment to sustainability.

Insights

- New Belgium Brewery in Fort Collins, Colorado, emphasizes environmental sustainability by utilizing innovative practices such as natural light in their brew house to reduce energy consumption and emissions while creating a conducive work environment.

- The brewery's commitment to sustainability extends to their brewing process, where they efficiently utilize by-products like wort for cattle feed, implement energy-saving techniques like a cone-shaped boiler plate, and treat process wastewater on-site to produce biogas for energy, showcasing a comprehensive approach to minimizing environmental impact.

Get key ideas from YouTube videos. It’s free

Recent questions

What is New Belgium brewery known for?

Sustainability and innovative brewing practices.

How does New Belgium brewery save energy?

Utilizing natural light and efficient brewing processes.

What happens to the liquid after mashing barley at New Belgium?

Transferred to a farmer for cattle feed.

How does New Belgium brewery treat process wastewater?

On-site in an anaerobic digester to produce methane-rich biogas.

What is the fermentation process at New Belgium brewery?

Yeast converting sugars to alcohol and CO2.

Related videos

Gardening Australia

Self sustainable zero waste productive home in Melbourne demonstrates future | Gardening Australia

Undecided with Matt Ferrell

Exploring Green Building and the Future of Construction

Kirsten Dirksen

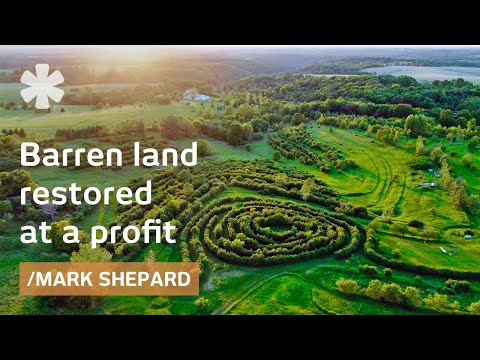

Homestead Paradise: got barren land, boosted it at a profit

Sustainability Illustrated

5 amazing biomimicry examples providing real sustainability solutions | Architecture Building Energy

Financial Times

8 Sustainability ideas that will change the world | FT Rethink

Summary

00:00

New Belgium Brewery: Sustainable Brewing Innovations

- New Belgium brewery in Fort Collins, Colorado, founded in 1991, prioritizes environmental stewardship alongside crafting beers like Satire and ABBL. They focus on innovation to save energy, water, and be a better employer, utilizing natural light in their brew house to reduce electricity bills, emissions, and enhance the work environment.

- The brewing process at New Belgium involves mashing barley to extract starches and sugars, then transferring the liquid, called wort, to a farmer for cattle feed. The brewery efficiently buffers different stages to avoid equipment shutdowns, and their unique cone-shaped boiler plate in the brew kettle speeds up boiling, saving energy.

- New Belgium's fermentation process involves yeast converting sugars to alcohol and CO2, with the resulting liquid sent to the bottling line. They reuse rinse water, treat process wastewater on-site in an anaerobic digester to produce methane-rich biogas for energy, showcasing their commitment to sustainability and minimizing environmental impact.