So Expensive Season 6 Marathon

Business Insider・65 minutes read

Agarwood is a valuable resin known as the wood of the gods, sourced from Aquilaria trees in Southeast Asia that are endangered due to unsustainable production. The global market for agarwood is estimated at $32 billion, with the price of aged ood oil reaching up to $80,000 per liter, projected to double to $64 billion by 2029.

Insights

- Agarwood, a valuable resin-infused wood, is produced by specific fungal infections in Aquilaria trees in Southeast Asia, with unsustainable production leading to critical endangerment of the trees.

- The global market for agarwood is estimated at $32 billion, with aged ood oil priced up to $80,000 per liter, expected to double to $64 billion by 2029.

- Coconut oil, once popular for health benefits, faced a price drop after warnings against saturated fats, but has since resurged with rising demand for products like alternative meats.

- Pule cheese, made from donkey and goat milk in Serbia, is expensive due to a labor-intensive process and the high cost of preserving the donkey species, with a secret recipe known by few.

Get key ideas from YouTube videos. It’s free

Recent questions

What is agarwood and why is it so expensive?

Agarwood, also known as the wood of the gods, is a valuable wood that can cost up to $100,000 per kilogram. It is produced when Aquilaria trees in Southeast Asia are infected by a specific fungal infection, resulting in resin-infused chips known as ood. Due to unsustainable production, all varieties of Aquilaria trees are critically endangered, with only 2% of wild trees adequately infected to produce agarwood naturally. In some forestries, like Truong's in Vietnam, Aquilaria trees are artificially inoculated to induce resin production. The global market for agarwood is estimated at $32 billion, with the price of aged ood oil reaching up to $80,000 per liter. The high cost is attributed to the labor-intensive process and the rarity of naturally produced agarwood.

How is Pule cheese made and why is it so expensive?

Pule cheese is a unique and expensive cheese made in the Zasavica Special Nature Reserve in Serbia. It is produced from 60% donkey milk and 40% goat milk, with only about 20 donkeys producing milk at a time, each yielding less than a gallon per day. To make one kilogram of Pule cheese, 6.6 gallons of milk are needed, and each donkey produces milk for only six months. The cheese is made using a secret recipe known by only Slobodan and one other person, requiring a mix of additives and bacteria to coagulate the milk. The high value of Pule cheese is also due to the cost of preserving the donkey species, with Slobodan spending about $100,000 annually to maintain the farm.

What is the process of making cuban link chains and why are they expensive?

Cuban link chains are symbols of luxury, with authentic ones being handmade in a few shops in Miami. Making a single cuban link chain requires over 5 experienced jewelers and can take over 12 hours. The process involves dangerous tasks like working with 1,000-degree flames and intricate soldering. Gold prices impact the cost of cuban link chains, with gold often alloyed with other metals for durability. The popularity of cuban link chains surged in recent years, becoming a status symbol in hip-hop and reggaeton culture. The demand for these chains remains high, leading to wait times of 5 to 7 weeks due to labor-intensive and time-consuming production processes.

What is vegetable tanning and why is vegetable-tanned leather more expensive?

Vegetable tanning is a traditional leather-making process dating back to 6000 BCE that uses natural tannins. Vegetable-tanned leather is considered higher quality and more durable than chrome-tanned leather. The process involves soaking hides in natural tannins for several weeks in wooden drums, leading to a unique patina and increased suppleness with age. Vegetable-tanned leather is more expensive due to its labor-intensive production process and unique aging properties. Artisans inspect, re-tan, dye, and grease the leather to adjust its elasticity, softness, and color, resulting in high-quality, long-lasting leather that meets specific standards for verification.

How are cashews harvested and why do their prices fluctuate?

Cashews are harvested once a year, with the shells containing toxic oil that makes splitting them open a challenging step. Factories used to manually split nuts to prevent machine damage, but this led to worker safety concerns. Advanced machines now crack shells cleanly, reducing risks to workers. Workers must roast cashews to destroy the toxic liquid and then peel off the husk by hand. Experienced workers can deskin about 2.5 kilograms of cashews per night. Cashews are graded by color, weight, and condition, with large whole nuts being the most valuable. Africa produces half of the world's cashew supply, with Ivory Coast exporting over 90% of its production. Vietnam is the largest cashew exporter globally, investing in automation to reduce manual labor. Climate challenges impact cashew production, but demand for cashews is expected to drive prices higher in the future.

Related videos

Business Insider

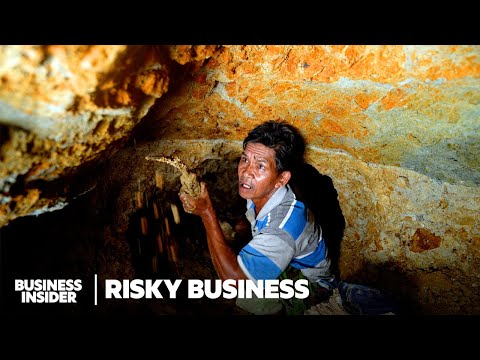

Why Hunting For 20-Million-Year-Old Petrified Wood Is So Dangerous In Indonesia | Risky Business

Business Insider

So Expensive Season 9 Marathon | So Expensive | Business Insider

Business Insider

The Petrified Forest #NationalPark has #petrifiedwood over 200 million years old. #Arizona

Business Insider

Why 5 Of The World's Priciest Salts And Spices Are So Expensive | So Expensive Food

Business Insider

Why Olive Wagyu Is So Expensive | So Expensive Food | Insider Business

Summary

00:00

Rare Agarwood: Costly Resin of the Gods

- Agarwood, known as the wood of the gods, can cost up to $100,000 per kilogram due to its infection process by mold, resulting in valuable resin called aloes.

- Aquilaria trees in Southeast Asia produce agarwood when infected by a specific fungal infection, leading to the creation of resin-infused chips known as ood, used in incense and high-value fragrances.

- Due to unsustainable production, all varieties of aquilaria trees are critically endangered, with only 2% of wild trees adequately infected to produce agarwood naturally.

- In some forestries, like Truong's in Vietnam, aquilaria trees are artificially inoculated to induce resin production, following agarwood's historical significance in various cultures and religions.

- The global market for agarwood is estimated at $32 billion, with the price of aged ood oil reaching up to $80,000 per liter, doubling to $64 billion by 2029.

- Lotus silk, extracted by hand from lotus flower stems in Vietnam, is a rare and expensive fabric, taking two months to produce enough for one scarf, costing 10 times more than regular silk.

- Gong making in Thailand involves intricate processes, including shaping, tuning, and hand-painting, with finely tuned gongs fetching tens of thousands of dollars, deeply rooted in Buddhism and popular in the West.

- Dong Tao chickens, known as dragon chickens, are raised in Vietnam for their unique meat and dramatic appearance, with the best selling for over $2,000 each, often entered into beauty competitions.

- Coconut oil's high price is attributed to the labor-intensive extraction process from coconuts, with the Philippines being a major producer, exporting to the US and Europe, doubling in price by the time it reaches Western markets.

- The surge in coconut oil's popularity in the West, driven by health claims, has led to a market demand that Filipino farmers struggle to meet, despite inconclusive scientific evidence on its health benefits.

28:16

Coconut oil demand rises despite health warnings

- Coconut oil contains 80 to 90% saturated fatty acids, with the American Heart Association advising against saturated fats in 2017, warning against coconut oil due to its cholesterol-increasing properties.

- Following the advisory, coconut oil's wholesale price dropped by over half, but it has since risen rapidly, becoming a key ingredient in products like alternative meats such as Beyond and Impossible Burgers.

- The majority of coconut trees in Asia, particularly in the Philippines, are nearing the end of their productive cycle, with many trees producing as few as 10 coconuts annually instead of the healthy 100 to 150.

- Planting new coconut trees is crucial due to the soaring demand, as it takes about 10 years for a new tree to fruit, with the market expected to grow by $518 million by 2024.

- Senmai, a traditional Vietnamese lacquer painting, uses toxic lacquer harvested from a specific region, requiring months of application and sanding back layers to build up the image.

- The process of making lacquer paint involves collecting resin from the toxic wax tree, mixing it for hours, and adding layers of paint and sanding them back to create depth, with natural ingredients like eggshells and cinnabar used for colors.

- Each Senmai painting is unique and unpredictable, with layers needing to dry fully before sanding, and the final piece polished with coal powder for a smooth finish.

- Stone crab claws are a pricey seafood, with fishers only able to harvest the claws while returning the bodies to the ocean, and the claws can regrow over time.

- Stone crab fishing is labor-intensive, with traps left in the water for two weeks before being pulled in, claws sorted, and only claws meeting the required size harvested to ensure sustainability.

- Ceylon cinnamon, named after Sri Lanka, is considered real cinnamon and requires delicate stripping of the inner bark by hand, with the thinner the quills, the more costly they are, while cassia cinnamon is a cheaper alternative with higher levels of coumarin.

50:17

Rare Pule Cheese, Opal, Bows, Bamboo Salt

- Pule cheese is unique and expensive due to being made in the Zasavica Special Nature Reserve in Serbia, founded by Slobodan Semic 24 years ago.

- Pule cheese is made from 60% donkey milk and 40% goat milk, with only about 20 donkeys producing milk at a time, each yielding less than a gallon per day.

- To make one kilogram of Pule cheese, 6.6 gallons of milk are needed, and each donkey produces milk for only six months.

- Pule cheese is made using a secret recipe known by only Slobodan and one other person, requiring a mix of additives and bacteria to coagulate the milk.

- The cost of preserving the donkey species adds to the high value of Pule cheese, with Slobodan spending about $100,000 annually to maintain the farm.

- Black opal, one of the most expensive gemstones, is primarily found in Lightning Ridge, Australia, with over 90% of the world's opal coming from there.

- Mining black opal is challenging and unpredictable, with miners drilling shafts and searching for trace amounts of opal to follow deeper into the rock.

- The value of black opal is determined by its color, brightness, and patterns, with the most valuable being bright red stones on a black base.

- Violin bows are complex and expensive due to the craftsmanship involved, with materials like Pernambuco wood from Brazil and horsehair from Mongolia being essential.

- Bamboo salt, used in Korean culture for cooking and traditional medicine, is made by roasting sea salt inside bamboo at high temperatures, with the nine times roasted version being the most expensive due to its labor-intensive process and health benefits.

01:12:59

Bamboo salt benefits and cuban link chains

- Bamboo salt contains higher levels of iron, potassium, and calcium compared to regular sea salt, potentially improving the immune system.

- Majority of bamboo salt is sodium chloride, with unclear potency of health benefits despite lower toxicity.

- WHO reported in 2016 that specialty salts like bamboo salt pose no toxicological risks but lack relevant nutritional benefits.

- Cuban link chains symbolize luxury, with an 18-carat gold chain worth $27,000 and some valued at ten times that.

- Making a single cuban link chain requires over 5 experienced jewelers and can take over 12 hours.

- Authentic and expensive cuban link chains are handmade in a few shops in Miami, requiring meticulous attention to detail.

- The process of making cuban link chains involves dangerous tasks like working with 1,000-degree flames and intricate soldering.

- Gold prices impact the cost of cuban link chains, with gold often alloyed with other metals for durability.

- The popularity of cuban link chains surged in recent years, becoming a status symbol in hip-hop and reggaeton culture.

- Demand for cuban link chains remains high, with wait times of 5 to 7 weeks due to labor-intensive and time-consuming production processes.

01:38:54

Crafting Cashews, Tanning Leather, Carving Chess: Traditions

- Splitting open cashew nuts is a challenging step due to the toxic oil coating the shells.

- Factories used to manually split nuts to prevent machine damage, but this led to worker safety concerns.

- Advanced machines now crack shells cleanly, reducing risks to workers.

- Workers must roast cashews to destroy toxic liquid and then peel off the husk by hand.

- Experienced workers can deskin about 2.5 kilograms of cashews per night.

- Cashews are graded by color, weight, and condition, with large whole nuts being most valuable.

- Cashews can only be harvested once a year, leading to fluctuating prices.

- Africa produces half of the world's cashew supply, with Ivory Coast exporting over 90% of its production.

- Vietnam is the largest cashew exporter globally, investing in automation to reduce manual labor.

- Climate challenges impact cashew production, but demand for cashews is expected to drive prices higher in the future.

- Vegetable tanning, dating back to 6000 BCE, is a traditional leather-making process using natural tannins.

- Vegetable-tanned leather is considered higher quality and more durable than chrome-tanned leather.

- Hides are soaked, de-haired, and tanned with natural tannins for several weeks in wooden drums.

- Vegetable-tanned leather develops a unique patina and becomes more supple with age.

- The process of vegetable tanning is time-consuming, leading to higher costs compared to chrome tanning.

- Artisans inspect, re-tan, dye, and grease the leather to adjust its elasticity, softness, and color.

- Vegetable-tanned leather is valued for its variations and authenticity, meeting specific standards for verification.

- The process of vegetable tanning aims to preserve a cultural craft and produce high-quality, long-lasting leather.

- Vegetable-tanned leather is more expensive due to its labor-intensive production and unique aging properties.

- The process of vegetable tanning requires skilled artisans to handcraft each piece meticulously.

- Chess pieces for the World Chess Championship sets are hand-carved by skilled artisans in India.

- Artisans undergo months of training to masterfully shape each chess piece, with less than 10 trusted to carve knights.

- The knight piece is the most detailed and time-consuming to produce, taking two hours per piece.

- The design of each chess piece, especially the knight, affects the overall value of the set.

- Specific height and width requirements for each chess piece are designed to meet international competition standards.

- The Staunton design is the only style allowed in international chess competitions today.

- Chess pieces used in championship matches have electronic coils for tracking moves, increasing their value.

- Weight and felt bottoms of chess pieces affect gameplay and value, making them easier to use effectively.

- Chess producers face challenges in finding skilled carvers, potentially leading to higher prices for hand-carved sets.

- The popularity of chess tournaments and media exposure, like "The Queen's Gambit," has increased demand for high-quality chess sets.