Making a Damascus San-Mai Kukri

Jesse Hu・21 minutes read

The Damascus San Mai kukri is created through a meticulous process of layering, welding, grinding, and heat treating, resulting in a unique and high-quality blade. The detailed steps include forging a 180-layer Billet, crafting the handle and guard with precision, and carefully finishing the blade for optimal hardness and aesthetics.

Insights

- Damascus San Mai kukri involves intricate layering techniques using Damascus steel and 1084 steel to create a unique pattern and ensure durability by welding layers together meticulously.

- The meticulous process of crafting the kukri involves precise steps like heat treating, hand sanding, and fitting the guard and handle, emphasizing attention to detail, quality control, and the use of specific tools and techniques to achieve a high-quality final product.

Get key ideas from YouTube videos. It’s free

Recent questions

How is a Damascus San Mai kukri made?

The Damascus San Mai kukri is crafted by layering three layers, two of which are Damascus, starting with 30 layers of alternating 1084 and 15 and 20. The layers are welded together with beads on corners and faces to prevent bowing, and the handle is welded to the Billet for stability. Quench oil is poured on the Billet before forging to create a protective soot layer, and the Billet is drawn out to around two feet, cut into six pieces for 180 layers. The Billet is then cut in half to sandwich three layers of 1084 in between, ensuring the core steel stays centered. The blade is thinned down, beveled, and ground with a unique pattern, followed by heat treating at specific temperatures for optimal hardness.

What is the purpose of using a press in making a Damascus San Mai kukri?

The press is used to isolate material for the blade and Tang in the process of making a Damascus San Mai kukri. It ensures alignment with the spine of the blade, allowing for precise shaping and control over the final product. By using a press, the craftsman can shape the blade and Tang according to the desired design and specifications, ensuring a high level of craftsmanship and quality in the finished kukri.

How is the guard of a Damascus San Mai kukri crafted?

Crafting the guard of a Damascus San Mai kukri involves ensuring flat transition faces, grinding the Tang to a shallower level than the ricasso, drilling holes with a quarter-inch drill bit, and connecting them with a round file. The guard is then shaped according to a leaf design, ensuring a unique and aesthetically pleasing appearance. Attention to detail and precision is crucial in crafting the guard to ensure a seamless and functional fit with the rest of the kukri.

What materials are used in making the handle of a Damascus San Mai kukri?

The handle of a Damascus San Mai kukri is crafted using a wooden block, copper, and epoxy. Holes are drilled into the wooden block, and sideward pressure is applied to connect them. Copper is inlaid into the softened tang to avoid difficulties later on, providing a durable and secure connection between the handle and the blade. The use of high-quality materials and meticulous craftsmanship ensures a strong and visually appealing handle for the kukri.

What is the final step in completing a Damascus San Mai kukri?

The final step in completing a Damascus San Mai kukri involves hand sanding all fittings, glueing up with 24-hour West system epoxy, drilling a hole for a stainless pin, hand sanding the handle, and darkening the guard with Perma Blue from Birchwood Casey. This meticulous process ensures that all components of the kukri are securely attached and finished to a high standard. The attention to detail in the final steps results in a beautifully crafted and functional Damascus San Mai kukri ready for use or display.

Related videos

FactoryTrip

퀄리티가 다르다! 칼매니아들이 인정하는 다마스커스 칼 제작 과정. 한국 수제 나이프 공방 / Amazing Korean handmade knife workshop

Jesse Hu

Making a $5000 Mosaic Damascus Cleaver

Tyrell Knifeworks

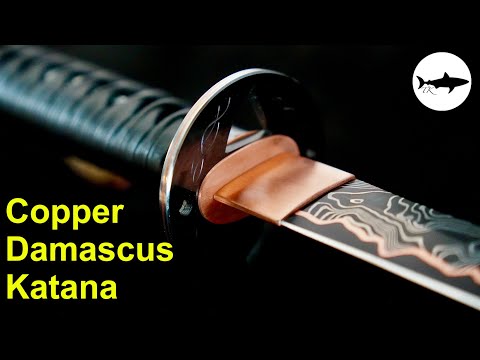

Forging a Copper Damascus Katana

Business Insider

Why Damascus Knives Are So Expensive | So Expensive | Insider Business

Kyle Royer

I'm Making The Most Beautiful Recurve Knife (Full Build)

Summary

00:00

Creating Damascus San Mai kukri with precision

- Damascus San Mai kukri involves three layers, two of which are Damascus, starting with 30 layers of alternating 1084 and 15 and 20.

- Welding the layers together with beads on corners and faces to prevent bowing, and welding the handle to the Billet for stability.

- Pouring quench oil on the Billet before forging to create a protective soot layer from burning off oil.

- Drawing out the Billet to around two feet, grinding off forward scale, and cutting it into six pieces for 180 layers.

- Grinding faces clean, except for the sides, using a welding magnet for high-temperature grinding.

- Arizona's hot weather affecting the shop temperature, leading to a cracked ceramic tile.

- Cutting the 180-layer Billet in half to sandwich three layers of 1084 in between, ensuring the core steel stays centered.

- Checking Forge welds for perfection before proceeding, as any delamination could be fixed at this stage.

- Using a press to isolate material for the blade and Tang, ensuring alignment with the spine.

- Thinning down the blade, beveling, and grinding shark teeth for a unique pattern, followed by final grinding and heat treating at specific temperatures for optimal hardness.

21:18

Blade Crafting Process: From Sanding to Finishing

- Hand sanding process allows for multitasking, progressing from 400 to 600 grit, spraying with fluid film to prevent rust, and wrapping in blue shop cloth and green masking tape.

- Fitting a guard involves ensuring flat transition faces, grinding the Tang to a shallower level than the ricasso, drilling holes with a quarter-inch drill bit, and connecting them with a round file.

- Crafting the wooden handle includes drilling holes into the wooden block, using sideward pressure to connect them, and inlaying copper into the softened tang to avoid difficulties later on.

- Profiling the guard involves shaping it according to a leaf shape design, while shaping the wooden handle requires profiling the block and etching a Maker's Mark using stencils and an etching machine.

- Finalizing the blade includes hand sanding all fittings, glueing up with 24-hour West system epoxy, drilling a hole for a stainless pin, hand sanding the handle, and darkening the guard with Perma Blue from Birchwood Casey.