I made a precision gearbox - with NO GEARS.

Not An Engineer・2 minutes read

Gears help with torque but can have backlash issues, while designing zero backlash cyclo drives can be costly but effective. Technologies like strain wave gearboxes and cyclo drives address backlash differently, with cyclo drives involving an eccentric shaft and Dow pins for smoother operation, facing challenges but improvements lead to a streamlined construction process.

Insights

- Designing a zero backlash cycal drive from scratch is costly but effective in resolving backlash, with the use of Dow pins simplifying the design and a 25 to 1 reduction ratio balancing speed and size.

- Replacing improvised plane bearings with Japanese tapered roller bearings significantly enhances cycloids' performance, emphasizing the importance of precision in machining and the transition to CNC machines for improved efficiency in the construction process.

Get key ideas from YouTube videos. It’s free

Recent questions

How do gears affect torque and speed?

Gears are used to increase torque and reduce speed in mechanical systems. However, one common issue with tooth gear systems is backlash, which can lead to inefficiencies and inaccuracies in operation.

What is a zero backlash cycal drive?

A zero backlash cycal drive is a mechanism designed to eliminate backlash in gear systems. While creating one from scratch can be costly, it is an effective solution to the common problem of backlash in tooth gear systems.

How do strain wave gearboxes and cycal drives differ?

Strain wave gearboxes and cycal drives are two technologies that address backlash issues in gear systems differently. While strain wave gearboxes use a flexible spline to transmit motion, cycal drives involve an eccentric shaft pushing a disc against rollers to drive output pins.

What is the significance of using Dow pins as rollers in a cycal drive?

Using Dow pins as rollers simplifies the design of a cycal drive, making the mechanism more efficient and easier to manufacture. This choice enhances the overall performance of the cycal drive system.

Why is a 25 to 1 reduction ratio chosen for a cycal drive?

A 25 to 1 reduction ratio is selected for a cycal drive to strike a balance between speed and size. This ratio ensures that the cycal drive operates effectively while maintaining the desired output speed and torque.

Related videos

من هنا نبدا القدرات

مقياس موهبة التروس و البكرات المحاضرة الثانية ( المستوى 2 و 3)

Ziroth

The Genius of Cycloidal Propellers: Future of Flight?

Game Maker's Toolkit

How Game Designers Solved These 11 Problems

The Efficient Engineer

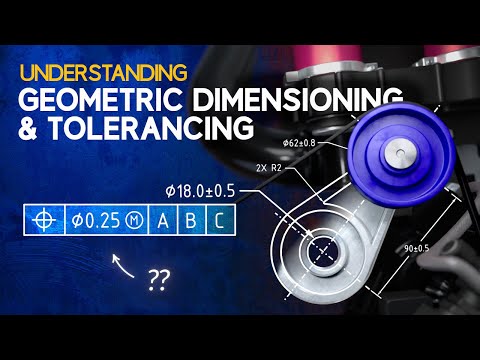

Understanding GD&T

Kris Harbour Natural Building

I Had To Rebuild The Waterwheel, The Driveshaft Snapped!

Summary

00:00

"Zero backlash cycal drive design challenges"

- Gears are suitable for increasing torque and reducing speed, but backlash is a common issue in tooth gear systems.

- Designing a zero backlash cycal drive from scratch is costly but effective in resolving backlash.

- Two existing technologies, strain wave gearboxes and cycal drives, address backlash issues differently.

- Cycal drives involve an eccentric shaft pushing a disc against rollers to drive output pins.

- Using Dow pins as rollers simplifies the design of the cycal drive.

- Designing a cycal disc involves creating a cycloid shape, specifically an epitrochoid for smoother operation.

- A 25 to 1 reduction ratio is chosen for the cycal drive to balance speed and size.

- Machining the housing and cycal discs involves precise measurements and careful execution.

- Creating custom tool holders for the lathe involves CNC machining services from PCB Way.

- The initial design of the cycal drive faced challenges due to rushed design decisions and material limitations.

16:19

Enhancing Cycloid Performance Through Precision Upgrades

- Replacing improvised plane bearings with Japanese tapered roller bearings was a significant decision to enhance the cycloids' performance.

- Consolidating all components into one package reduces the chances of misalignment and simplifies the construction process.

- Learning from past mistakes, the importance of knowing when to start over was highlighted, as seen when a ream snapped 20 mil and 45 minutes into the housing construction.

- Transitioning from drilling to milling and using a boring head resulted in a superior finish on the roller seats.

- Shifting to a CNC machine allowed for running both cycles simultaneously, streamlining the process.

- Utilizing manual draw bars and precise measurements ensured accuracy in creating the discs and housing components.

- The meticulous process of lapping and machining the spindle and bearings was detailed, emphasizing precision and attention to detail.