How Cooling Towers Work

The Engineering Mindset・8 minutes read

Cooling towers operate by circulating warm water from a chiller through a system that releases heat and condenses water, with components like fans, motors, and drift eliminators essential for the process to function efficiently. The design criteria dictate the type of cooling tower used in various buildings, ensuring the proper operation and maintenance of the system to reduce operating costs and maintain functionality.

Insights

- The operation of a cooling tower involves warm water from a chiller passing through spray nozzles onto fill packaging to lose heat, while cooler air is drawn in to pick up heat and become humid, forming a continuous loop of cooling process.

- Key components of a cooling tower include a fan for air circulation, fill packaging to enhance heat exchange, and a basin with various features like water inlet, overflow prevention, and drift eliminators to manage water and air quality efficiently.

Get key ideas from YouTube videos. It’s free

Recent questions

How does a cooling tower operate?

Cooling towers operate by taking warm water from a chiller containing building heat, distributing it over fill packaging through spray nozzles. The water loses heat as it drips into a basin, where cooler condenser water is collected and sent back to the chiller in a continuous loop. Cooler air is sucked in, passes opposite the condenser water, picks up heat, and becomes humid. Drift eliminators condense water to reduce operating costs, while the humid air is rejected by a fan into the atmosphere.

What is the purpose of a drift eliminator in a cooling tower?

The drift eliminator in a cooling tower serves to condense water to reclaim and reduce operating costs. It helps in separating water droplets from the air stream, preventing water loss and reducing the amount of water vapor released into the atmosphere. This component plays a crucial role in maintaining the efficiency and effectiveness of the cooling tower system.

What are the key components of a cooling tower?

The key components of a cooling tower include a fan that pulls air in, an inlet shield that filters the air, a motor that drives the fan, a header through which condenser water enters, and spray nozzles that distribute the water onto fill packaging. The fill packaging increases the surface area for air to pull heat from the water, while the basin collects the water as it drips down. Drift eliminators help in removing moisture from the air before it exits the cooling tower.

How is the condenser water in a cooling tower maintained?

The condenser water in a cooling tower is maintained through various mechanisms. The tower includes an outlet for the condenser water return, a water inlet with a ball valve to regulate and maintain the water level, an overflow to prevent overflow situations, and a drain to remove salts and bacteria buildup. These components work together to ensure the proper functioning and cleanliness of the condenser water in the cooling tower system.

What determines the type of cooling tower used in buildings?

The type of cooling tower used in buildings is determined by design criteria specific to each structure. Factors such as the cooling load requirements, space availability, environmental conditions, and budget constraints play a role in selecting the appropriate cooling tower. Different types of cooling towers offer varying levels of efficiency, capacity, and operational costs, making it essential to consider these factors when choosing the right cooling tower for a building.

Related videos

saVRee

How Cooling Towers Work (Working Principle)

The Engineering Mindset

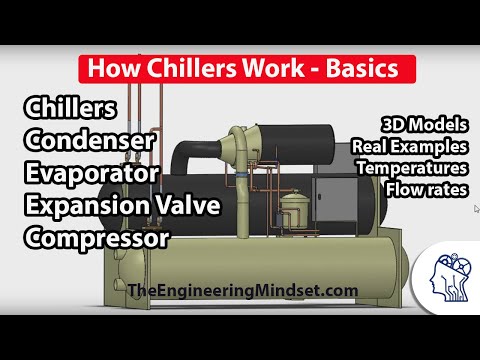

Chiller Basics - How they work

The Engineering Mindset

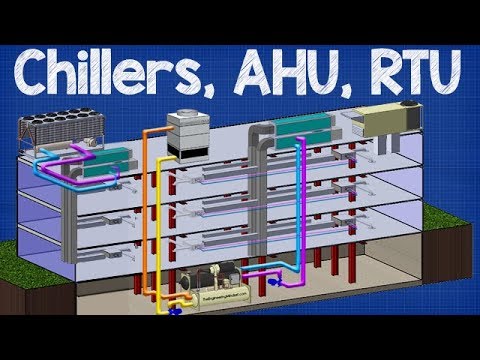

How Chiller, AHU, RTU work - working principle Air handling unit, rooftop unit hvac system

The Engineering Mindset

Chilled Water Schematics - How to read hvac engineering drawing diagram

The Engineering Mindset

Absorption Chiller, How it works - working principle hvac

Summary

00:00

Cooling Tower Operation: Efficient Heat Exchange System

- Cooling tower operation overview: Warm water from chiller containing building heat enters header, passes through spray nozzle, distributed over packaging, loses heat, drips into basin, cooler condenser water collected, sent back to chiller in continuous loop.

- Cooler air sucked in, passes opposite direction of condenser water, picks up heat, becomes humid and moist.

- Drift eliminator condenses water to reclaim and reduce operating costs, humid air rejected by fan into atmosphere.

- Cooling towers used in various buildings, design criteria determine type of cooling tower.

- Components of cooling tower: fan pulls air in, inlet shield filters air, motor drives fan, condenser water enters header, sprayed through nozzles onto fill packaging.

- Fill packaging increases surface area for air to pull heat from water, water drips down to basin, warm air exits through drift eliminators.

- Basin includes outlet for condenser water return, water inlet with ball valve to maintain water level, overflow to prevent overflow, drain to remove salts and bacteria buildup.