Gold Prospecting To Pouring Gold Bars! HELICOPTER SAMPLE!!!

mbmmllc・56 minutes read

Jason from M Baker Mining Medals goes on a two-year gold prospecting adventure with a friend, finds a rich gold vein, processes the ore using various techniques, and ends up with a total gold weight of 66.4 grams, surpassing the break-even point.

Insights

- Prospecting for gold involved a complex process of identifying high-grade zones within a vein, crushing rocks to extract gold, and using various techniques like shaker tables and vibrating tube mills to separate gold from other materials.

- The extraction process included steps such as smelting the crushed material with additives, pouring it into a mold, and collecting the precious metals, with the final yield calculated to be 45.3 grams of gold per ton of ore, showcasing the intricate nature of gold extraction processes.

Get key ideas from YouTube videos. It’s free

Recent questions

How did the gold prospecting adventure begin?

With a friend's map to a lost gold vein.

What was the narrator's method for identifying gold-rich rocks?

Breaking rocks to find visible gold spots.

How did the narrator extract gold from the rocks?

By crushing, running through a shaker table, and using a magnet.

What was the final step in the gold extraction process?

Pouring the molten material into a mold.

What was the narrator's total gold yield per ton of ore?

45.3 grams of gold per ton.

Related videos

Summary

00:00

Jason's Gold Prospecting Adventure: A Journey

- The gold prospecting adventure took 2 years and over $4,000 to complete.

- A friend provided a map to a lost gold vein, which was found and prospected.

- A helicopter was rented to transport the gold off the mountain for processing.

- The goal was to pour gold bars and see if striking it rich was possible.

- Jason from M Baker Mining Medals embarked on the prospecting adventure.

- The journey involved bushwhacking through challenging terrain.

- Finding quartz float on a Talis slope indicated the right direction.

- Quartz float pieces were discovered, signaling proximity to the gold vein.

- Prospecting involved breaking open quartz pieces to identify mineralization.

- Identifying high-grade zones within the vein was crucial for successful prospecting.

16:18

"Extracting Gold: Crushing Rocks for Riches"

- The narrator finds a piece of gold while breaking rocks and identifies a rich spot with visible gold.

- They continue breaking rocks and find gold in various sections, particularly near the foot wall.

- The narrator discovers gold laced through rocks and decides to crush them to extract more gold.

- They differentiate between good gold-containing rocks near the foot wall and less valuable material above.

- The narrator separates the good material from the junk and plans to crush it further for gold extraction.

- After crushing the rocks, the narrator handpicks through the material but is disappointed by the lack of visible gold.

- They find some gold in the rocks but not as much as expected, especially in larger pieces.

- The narrator uses a vibrating tube mill to further crush the material and extract more gold.

- They run the crushed material through a shaker table to separate gold from the tailings.

- The narrator uses a magnet to remove any steel or magnetic particles before running the tailings on the shaker table to scavenge for more gold.

31:32

Gold Extraction Process in North Cascades Adventure

- The speaker pans down material through a disc mill, finding a nice piece of gold that went through the mill.

- They combine all the gold found and use a snuffer bottle to extract it, then clean it with a shop towel before putting it in a furnace.

- Bismuth is added to the gold to be melted in a furnace, where bismuth oxide is absorbed by a cupel, leaving the gold and silver as a button on the surface.

- The speaker calculates the gold content in the sample, finding it to be about 56 grams per ton.

- The speaker goes on a prospecting adventure with a friend, Dan, in the North Cascades, looking for free gold in quartz.

- Using feather and wedges, they break off chunks of quartz from a vein, finding some gold in the process.

- They continue prospecting, finding more gold in quartz pockets and planning to assay a sample for potential extraction.

- The speaker crushes the ore using a jaw crusher and a hammer mill, then runs it through a shaker table to separate the gold and other minerals.

- After the separation process, they combine the concentrates and smelt them with various additives to collect the gold and silver.

- The final step involves pouring the molten material into a mold, allowing the lead to collect the precious metals at the bottom for separation.

47:06

Gold Extraction Process from Quartz Ore

- The process begins by putting the slag in the cupel furnace.

- A big spike is accidentally dropped into the slag and needs to be retrieved.

- Lead is found at the bottom of the furnace, weighing 28 grams.

- The lead will melt and oxidize in the furnace, with the oxides absorbed by the cupel.

- A precious metal bead is left in the cupel after the process.

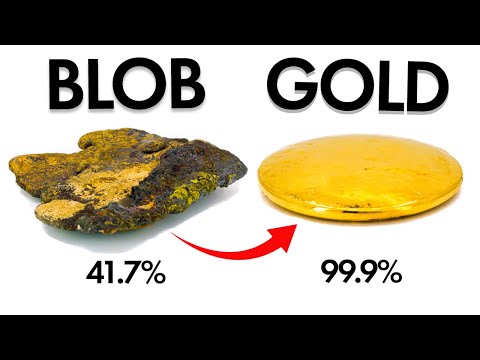

- The bead weighs 68 grams, estimated to be about 80% gold.

- Calculations show a yield of 45.3 grams of gold per ton of ore.

- The plan involves collecting quartz float from a rich vein for processing.

- Bags of quartz float are collected and staged for helicopter transport.

- The process involves crushing, hammer milling, and using a shaker table to extract gold from the ore.

01:08:13

"Finding Gold in Shop Samples"

- The speaker takes viewers to a shop to search for gold and then proceeds to pan out the number one and number two samples to find gold.

- The ore in number two is oxidized, making it easier to pan for gold due to the lack of sulfides.

- After panning, the speaker separates the gold from number one and number two to weigh them separately.

- The gold is cleaned using a Snuffer bottle and then mixed with bismuth to remove impurities in a celling furnace.

- The gold is then placed in a cupel in the furnace to determine the total amount of gold obtained.

- The speaker then shifts focus to cutting rocks and finding gold associated with silver sulfides in the samples.

- The final gold weight obtained from both number one and number two samples is 66.4 grams, exceeding the break-even point of 60 grams.