1940s Metal Lathe [Restoration]

Hand Tool Rescue・2 minutes read

The text outlines a detailed process for refurbishing a milling machine, including steps like applying primer and enamel paint, using specific products like wax and maple syrup, and installing various components like bronze bushings and a spacer. It emphasizes following the manual's instructions carefully to achieve optimal results and ensure proper functioning of the machine.

Insights

- The restoration process detailed in the text involves intricate steps such as utilizing unconventional materials like wax and maple syrup, emphasizing the importance of precise techniques like ensuring flat surfaces and centering components according to the manual.

- Key components such as bronze bushings, spacers, and dead-center play a crucial role in the restoration process, highlighting the meticulous attention to detail required for successful completion.

Get key ideas from YouTube videos. It’s free

Recent questions

How do I restore metal parts?

By fixing with new bushings, removing rust, applying primer, and painting.

What are the specific steps for restoration?

Use wax, ensure flat surfaces, apply maple syrup, and use oil instead of grease.

What materials are needed for restoration?

Spacer, bronze bushings, dead-center, tailstock, and cutter.

How many coats of paint are required?

Four coats of grey enamel paint are needed.

What is the purpose of self-etching primer?

It is used to prepare the metal surface for painting.

Related videos

Abom79

SNS 322 Machining Rucker Straight Edge

IvanzeD TV

PROPER CARE AND MAINTAINANCE OF DRAFTING TOOLS SUPPLIES AND EQUIPMENT | TLE PERFORMANCE TASK | SLHS

CAD CAM TUTORIAL BY MAHTABALAM

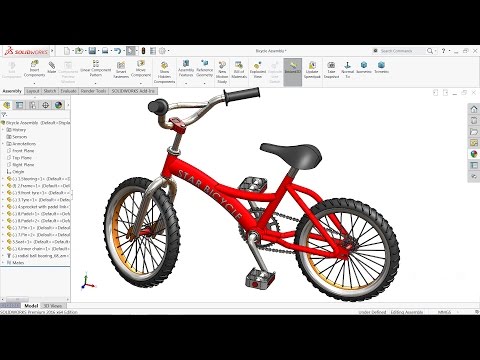

Solidworks tutorial | Design and Assembly of Bicycle in Solidworks

Jim's Automotive Machine Shop, Inc.

The LAST Rebuild Ran 10 Miles... Will The 235 Chevy Last THIS Time?

Hand Tool Rescue

1920s Rare Battery Charger [Restoration]

Summary

00:00

Restoring Lathe: Bushings, Primer, Enamel, Maintenance Steps

- The process involves fixing parts with new bushings, removing rust, applying self-etching primer, and four coats of grey enamel paint. Specific steps include using wax instead of paint, ensuring flat machined surfaces, applying maple syrup, and using oil instead of grease as per the manual. Additionally, the text mentions the installation of a spacer, bronze bushings, and a dead-center from the spindle, along with centering the tailstock and cutter.