三相モータを作るプロセス。日本の産業用設備や社会インフラを支えるモータ工場。

プロセスX・2 minutes read

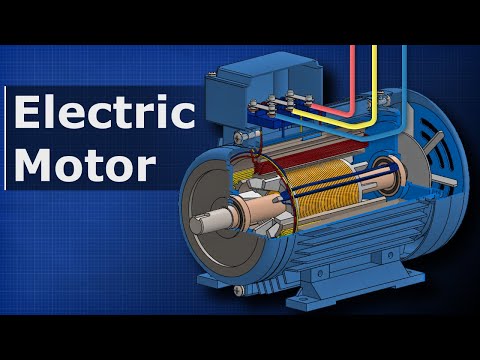

Mitsubishi Electric produces oxygen motors for industrial and social infrastructure through a detailed manufacturing process involving forming, welding, pressing, winding, painting, and rigorous testing. The process includes specific steps like using a 400-ton press, insulation slots, coil winding, shaft machining, heating components, rotor balancing, anti-rust paint application, and thorough electrical tests and inspections.

Insights

- Mitsubishi Electric, a Japanese manufacturer, plays a pivotal role in producing oxygen motors vital for industrial and social infrastructure, involving intricate steps like welding, pressing, winding coil wire, and rigorous testing.

- The meticulous manufacturing process of these motors encompasses precise actions such as using a 400-ton press, balancing rotors, applying anti-rust paint, and conducting thorough electrical tests and visual inspections, ensuring quality and reliability before shipping.

Get key ideas from YouTube videos. It’s free

Recent questions

How does Mitsubishi Electric manufacture oxygen motors?

Mitsubishi Electric manufactures oxygen motors by forming a steel plate into a cylindrical shape, welding the frame, pressing the iron core, winding coil wire, conducting electrical tests, and painting.

What are the key steps in producing oxygen motors?

The key steps in producing oxygen motors include using a 400-ton press for the iron core, installing insulation slots, winding coil wire, machining the shaft, heating components, balancing the rotor, applying anti-rust paint, and conducting tests before shipping.

Why is the welding process important in oxygen motor production?

The welding process is crucial in oxygen motor production as it helps in forming the frame, ensuring structural integrity, and providing a sturdy foundation for the motor components.

What is the significance of conducting electrical tests in manufacturing oxygen motors?

Conducting electrical tests in manufacturing oxygen motors is essential to ensure the functionality, safety, and efficiency of the motors before they are assembled and shipped for industrial and social infrastructure use.

How does Mitsubishi Electric ensure quality control in oxygen motor production?

Mitsubishi Electric ensures quality control in oxygen motor production by conducting visual inspections, balancing the rotor, applying anti-rust paint, and subjecting the motors to rigorous electrical tests to meet industry standards and customer requirements.

Related videos

Summary

00:00

Mitsubishi Electric: Oxygen Motors Manufacturing Process

- Mitsubishi Electric, a Japanese electrical manufacturer, produces oxygen motors crucial for industrial and social infrastructure. The process involves forming a steel plate into a cylindrical shape, welding the frame, pressing the iron core, winding coil wire, and conducting electrical tests before assembly and painting.

- The manufacturing process includes specific steps like using a 400-ton press for the iron core, installing insulation slots, winding coil wire for the stator, machining the shaft to specified dimensions, heating components to over 300 degrees, balancing the rotor, applying anti-rust paint, and conducting electrical tests and visual inspections before shipping the finished three-phase motors.